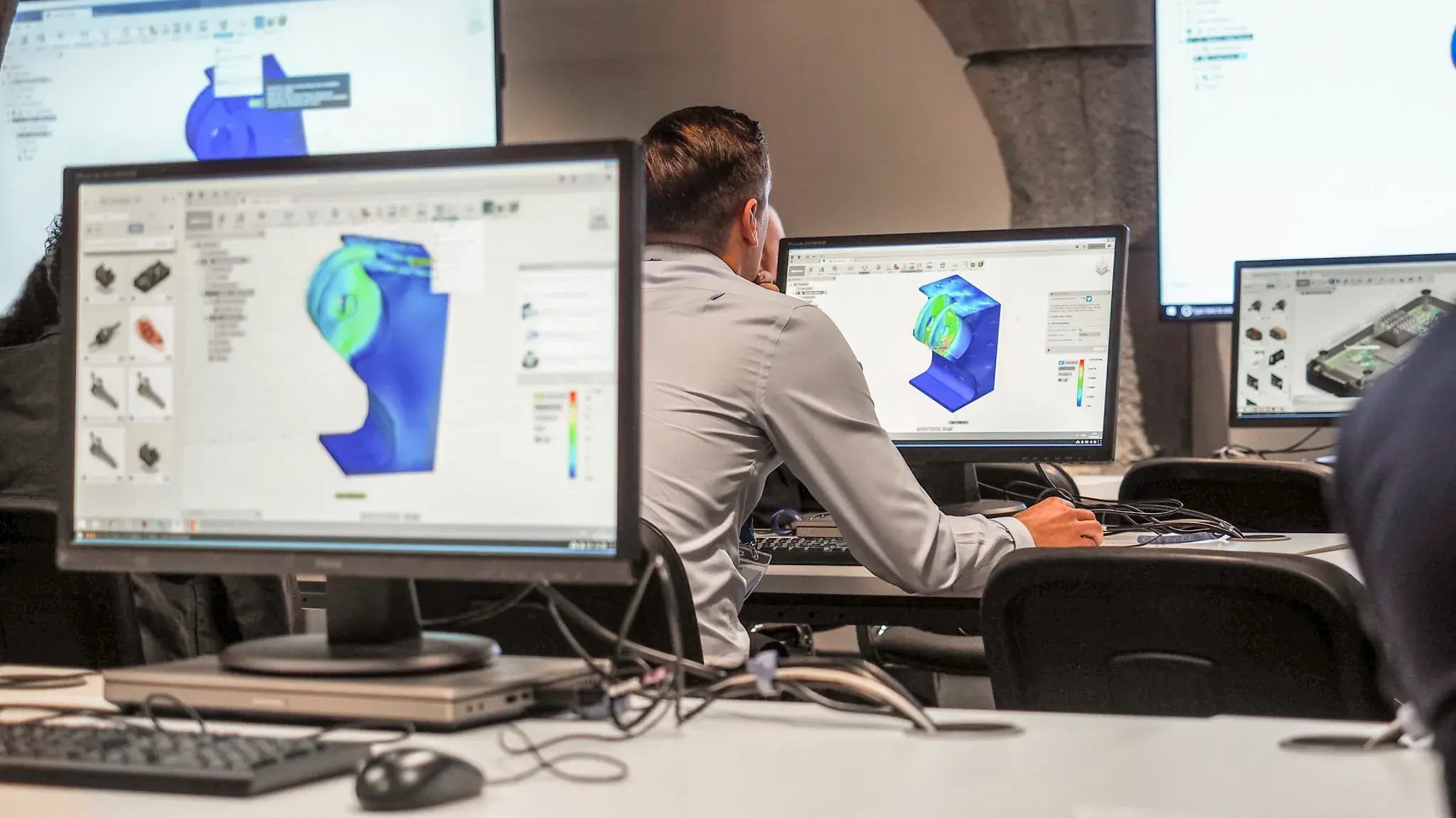

Fusion Milling and Turning Training

Virtual, machinist-led training in Fusion CAM, Milling, Turning, and best practices for real production environments.

Milling Training

Milling Training

Expert-led training to gain complete mastery of Fusion CAM, from 2D fundamentals to advanced 3D surface machining. Learn how to set up parts, generate toolpaths, and verify G-code ready for real production.

You’ll Learn:

- Interface navigation, preferences, and data management

- Setup creation, stock control, and multi-setup workflows

- 2D Adaptive, Contour, Pocket, Slot, and Hole making strategies

- Chamfering, engraving, and finishing operations

- 3D Adaptive roughing and surface finishing (Parallel, Contour, Steep & Shallow, Flow, Scallop)

- Simulation and G-code post-processing for error-free output

Spread out over the course of 2 full work days and conducted via virtual Zoom meetings, the Fusion Milling Training sessions are offered in both EST and PST start times.

Turning Training

Turning Training

Learn to program precise lathe operations in Fusion’s Turning workspace, perfect for machinists expanding beyond milling or standardizing shop workflows.

You’ll Learn:

- Turning workspace setup, stock, and chuck configuration

- Facing, roughing, and finishing profiles

- Grooving, boring, and cycle optimization

- Tool selection, offsets, and simulation verification

- Post-processing and G-code export for production lathes

Gain the skills to confidently program and verify complete turning operations ready for the spindle.

Taking place during 1 work day and conducted via a virtual Zoom meeting, the Fusion Turning Training sessions are offered in both EST and PST start times.